Products

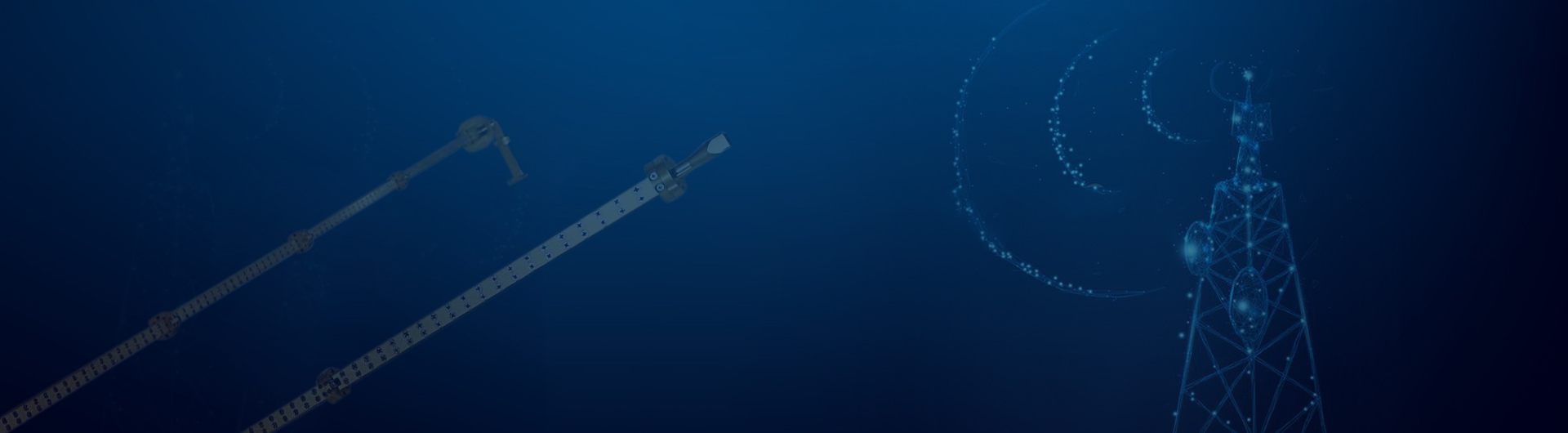

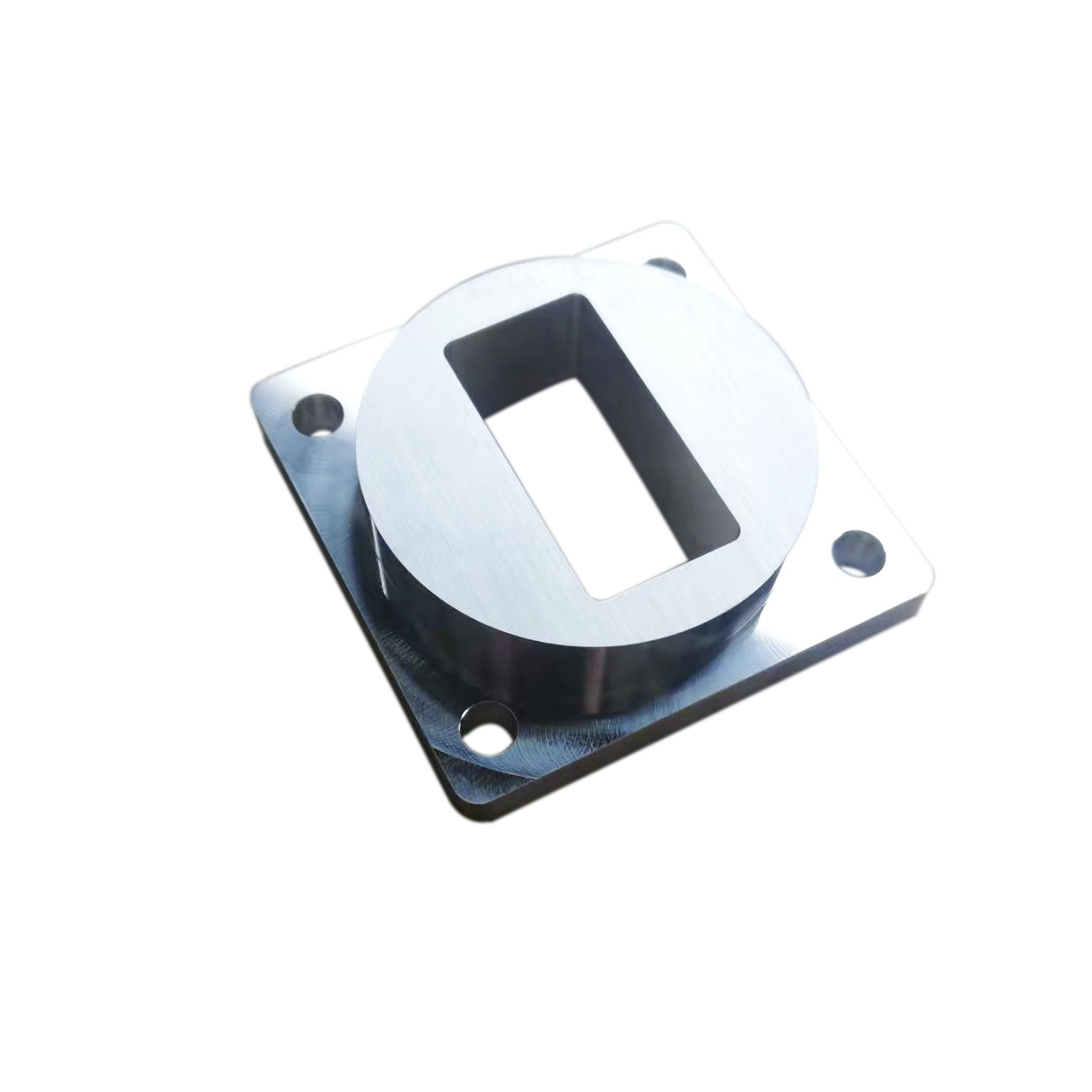

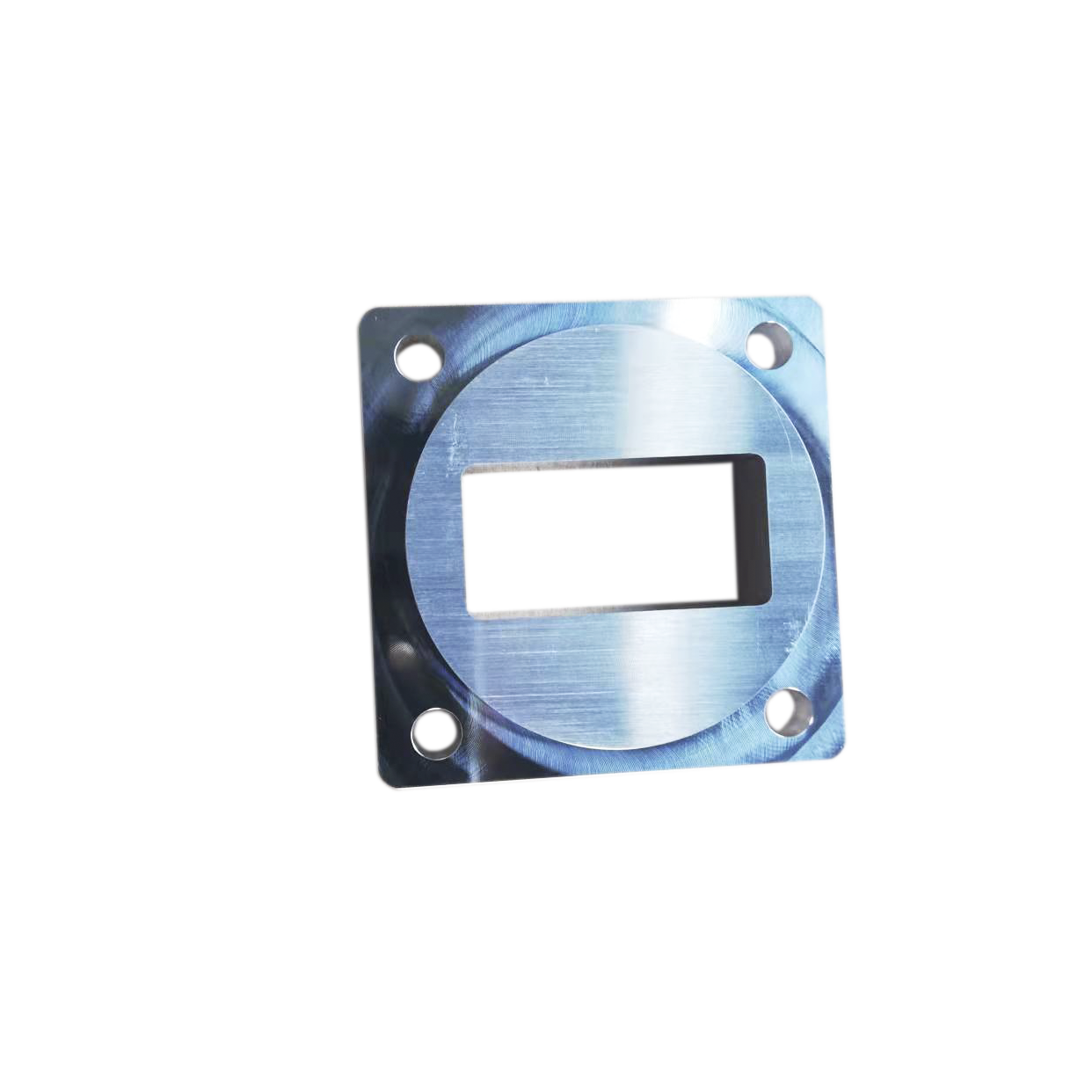

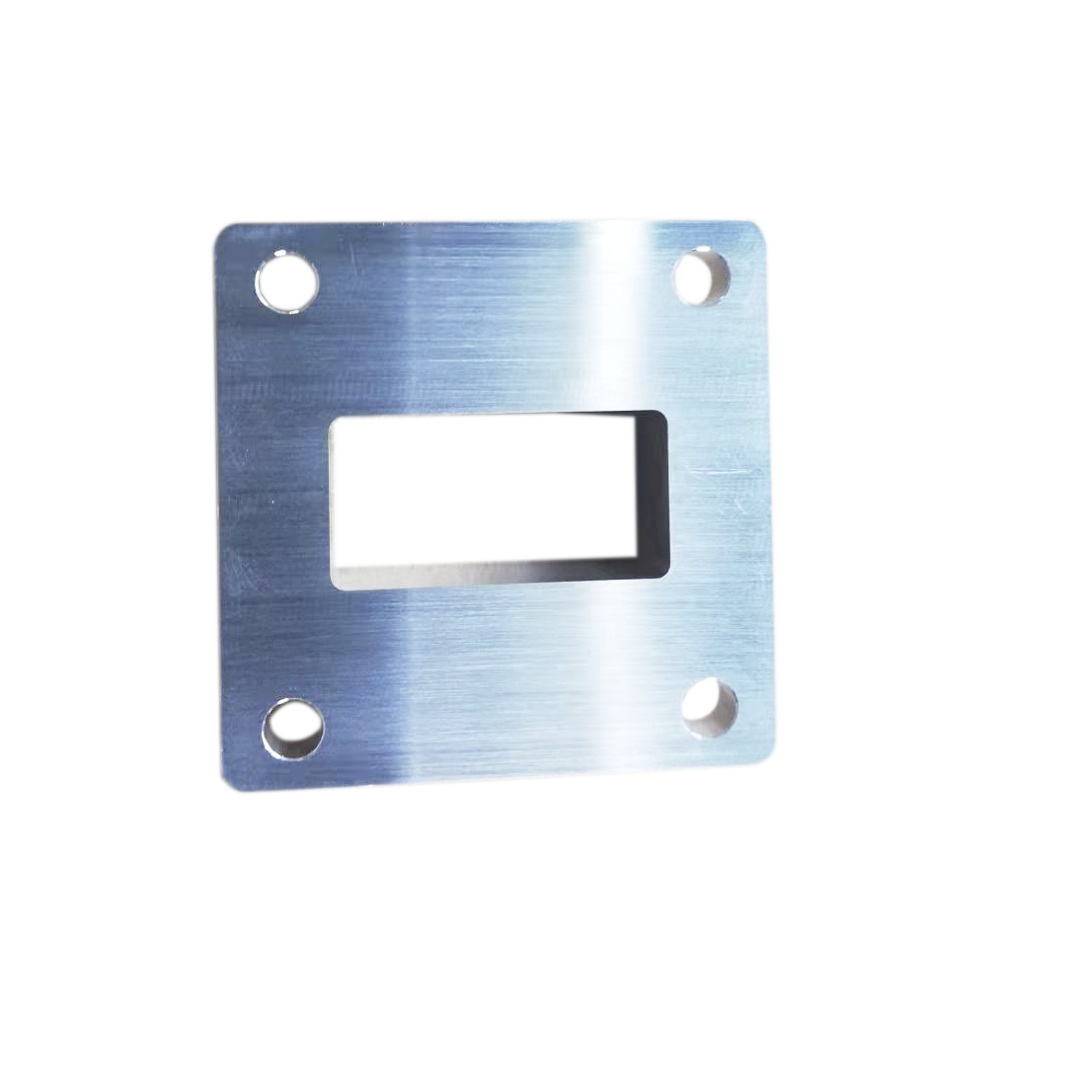

Quality Inspection for Aluminum Cavity Cnc Machining - WR90 standard welded waveguide flange – XIXIA

Quality Inspection for Aluminum Cavity Cnc Machining - WR90 standard welded waveguide flange – XIXIA Detail:

Connector of waveguide flange:

After obtaining appropriate waveguide components, the assembly and maintenance of waveguide components and interconnection devices will also affect the performance. The connector of waveguide flange is a problem prone area. If gaskets are not used, the surface of the flange needs to be kept clean and flat. Any damage, dust, or peeling of the metal plate may cause RF leakage, and misalignment may degrade performance. The bending and distortion of the waveguide may also form stress cracks due to thermal cycling and mechanical stress. The higher the frequency of the waveguide, the more sensitive the system performance is to correct assembly and maintenance.

For example, for a waveguide with a flange connection, each corner of the waveguide has a specified torque. If one corner of the waveguide has more and less torque than the other, a small gap will reduce the VSWR and insertion loss performance. RF leakage may also occur. This may occur when the gasket gradually deteriorates with age or after heating and cooling cycles. Some threaded screws still support even under vibration and heavy load. The method of ensuring stable fastening can be adopted as long as it does not affect the RF performance and flange clamping.

Product detail pictures:

Related Product Guide:

Our goods are broadly recognized and reliable by users and can meet consistently switching financial and social demands of Quality Inspection for Aluminum Cavity Cnc Machining - WR90 standard welded waveguide flange – XIXIA , The product will supply to all over the world, such as: Jordan, Leicester, Ecuador, We are in continuous service to our growing local and international clients. We aim to be worldwide leader in this industry and with this mind; it is our great pleasure to serve and bringing the highest satisfaction rates among the growing market.

We have been looking for a professional and responsible supplier, and now we find it.